A WORLD OF TECHNOLOGY

About Elman

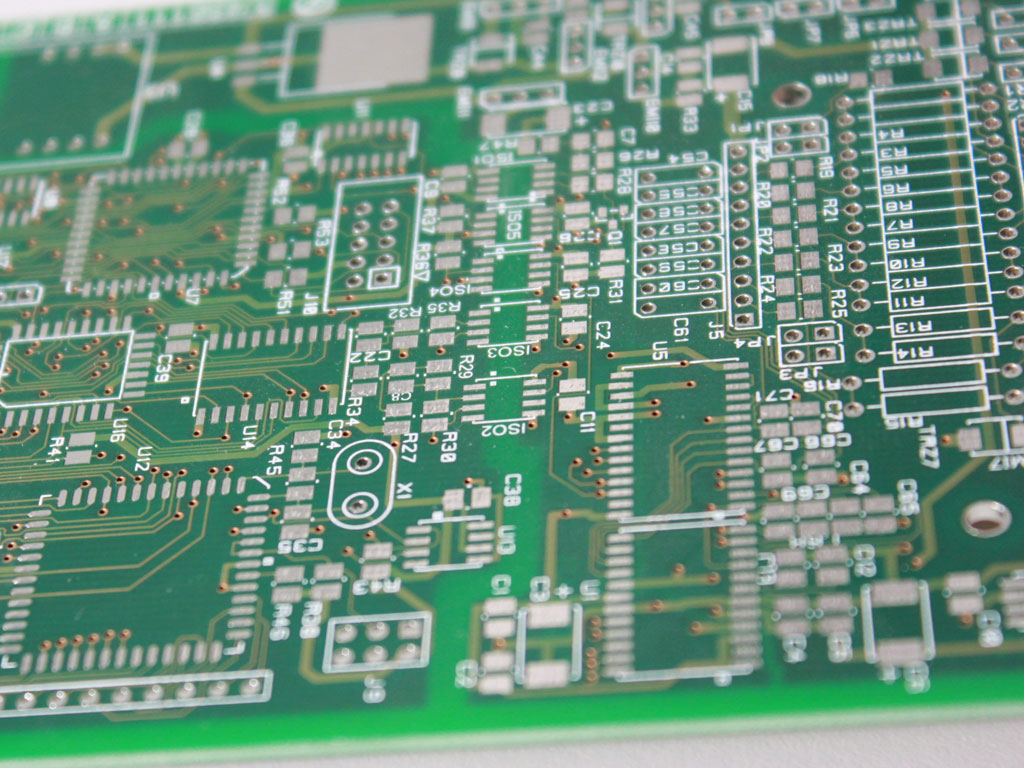

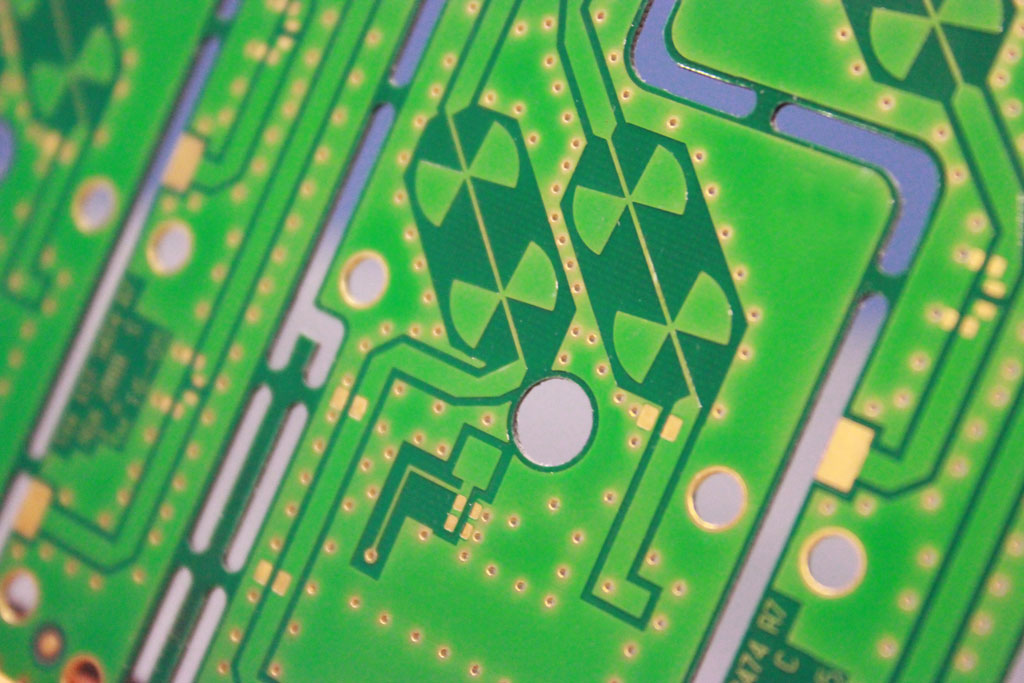

Elman operates in Abruzzo (Italy) and produces printed circuits board since 1991. In recent years we have invested heavily in Research and Development and focused our attention on thermal dissipation systems with different degrees of electrical insulation to be applied to various bilayer and multilayer supports.

Our products are made entirely in the Italian factory, offering both sampling and series production services.

Highlights

• Staff with thirty years of experience in PCBs manufacturing

• Latest generation production systems (Orbotech Incam Pro, Shmoll Direct

Imagin, Caoduro Electrolytic Copper, Atg Flying Probe Tester, Pluritec Inspecta

Combo, Orbotech Dimension 6 AOI, Wise Etching System)

• Selective hole filling with electrolytic copper

• High thickness Pcbs

• Heavy copper up to 1mm

• Customer support for product design and development

• R&D

HDI

• BGA layout, high layer count and complex stackups

• Back drilled holes

• Resin Filled and Capped vias

• Aspect radio PHT ≥ 10

• Aspect Radio blind vias ≥ 0,9

Certifications

Company is Iso9001:2015 certified since 1996. Elman owns UL796 certification also for Canadian and USA market on standard FR4, LeadFree, medium and high Tg and IMS materials for LED applications.

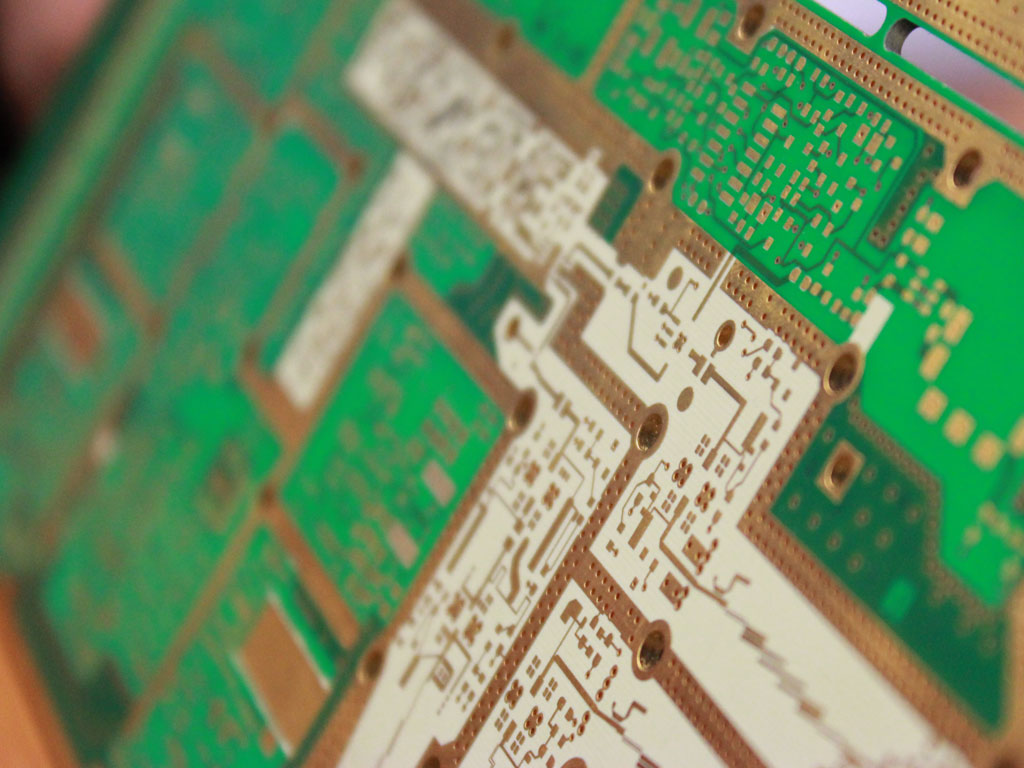

Base material

- Epoxy laminates:

Standard FR4, Mid Tg, High Tg, Halogen Free - High Speed application:

Panasonic Megtron 6 and Megtron 7; Isola Astra and I-Tera, IS600(Series) FR408HR; Nelco N4000-13(SI) & N4800-20-(SI)

- High Frequency materials Teflon based and non-Teflon based:

Rogers/Arlon (w/wo Copper/Al/Brass support). RT Duroid RO3000, RO4000, RO6000, DiClad, AD, TC, CuClad

Taconic: RF35, RF35A2, RF45, RF60, RF60TC, FastRise, TLX, TLY, TLE, TSM-DS3, Tacbond 1.5

Nelco: Mercurywave, Meteorwave Series

- High performances materials for avionic/military applications:

Polyimide Resin Systems: Arlon 33N, 35N, 84N, 85N, 85HP; Isola P95/P96

- Special materials:

Foam: Rohacell HF Polymethacrylimide (PMI), General Plastics RF-2200

Polyurethane, Laird Eccosorb Microwave Absorber LS Series

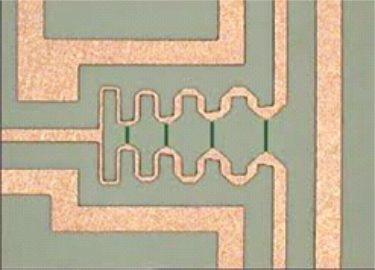

Techniques for coins insertion in PCBs

Integrating heat dissipation coins into the printed circuit board structure is a proven and reliable technique and provides a highly efficient way to dissipate heat from electronic components.

Increased efficency of the components

Increased life time of the components

Reduction of device failures

Reduction of heatsink size

Reduction of apparatus size

Integration of control circuitry in main boards

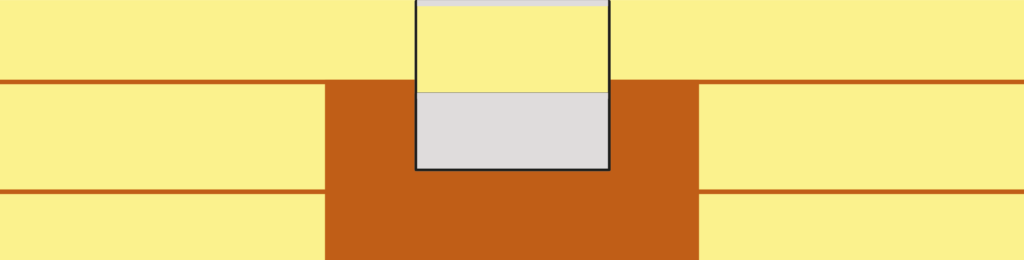

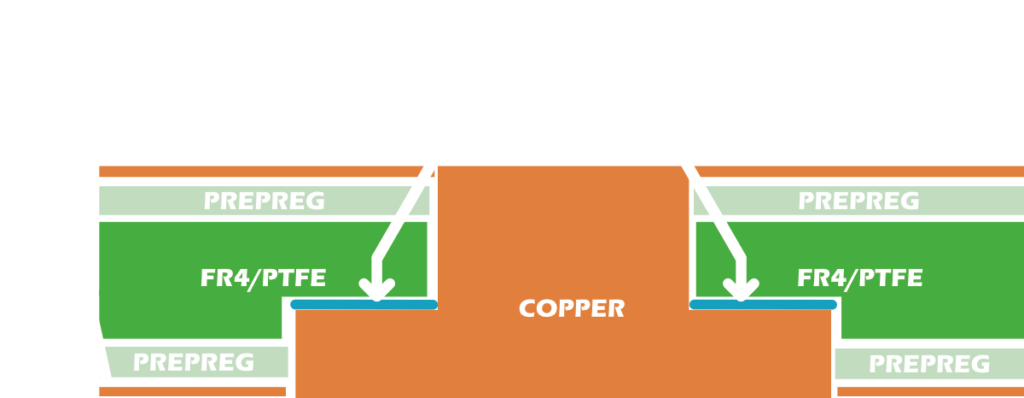

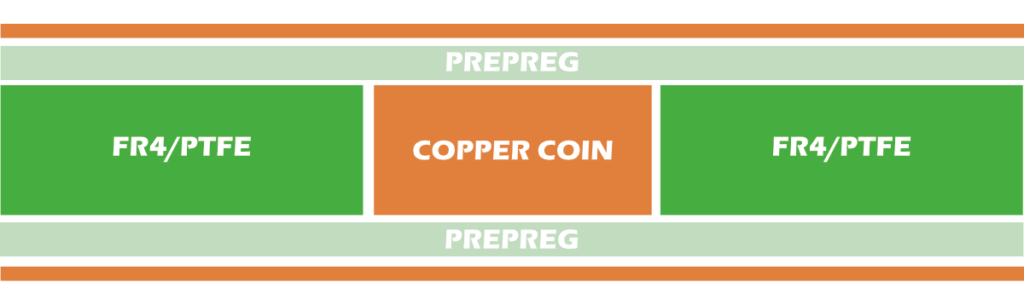

Types of Coin

1. Copper coin inserted in FR4 or Hybrid multilayer: the coin create an optimized path

for the heat dissipation towards the heat sink.

Insertion techniques and configurations:

• Adhesive

• Lamination

• Press-Fit

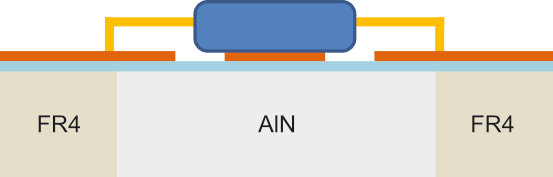

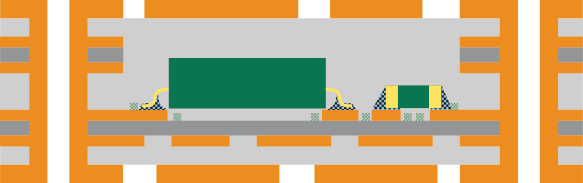

• Cavity in Coin

2. Ceramic Coin (Alumina Al2O3 or Aluminum Nitride AIN) inserted in FR4 or Hybrid multylayer: it allows to reach a high integration of the power modules in the board, maintaining a high degree of thermal conductivity with a high electrical insulation.

3. FR4 coin in IMS or multilayer with metal core: it allows to get electrical insulation through conductive layers.

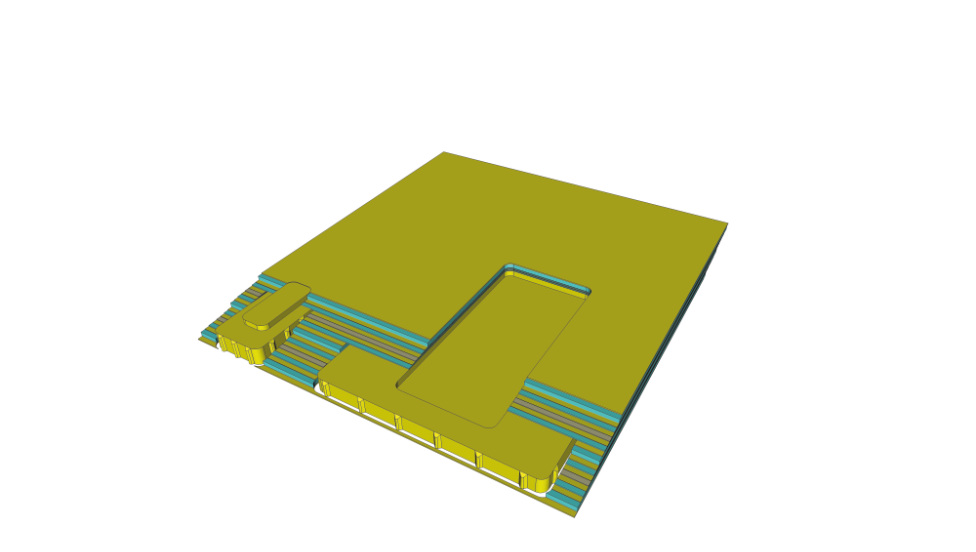

Embedded components

• Embedded Resistences with OhmegaPly® and Ticer Technology ®

• Integration of active and passive components in SMD technology with soldering process

R&D

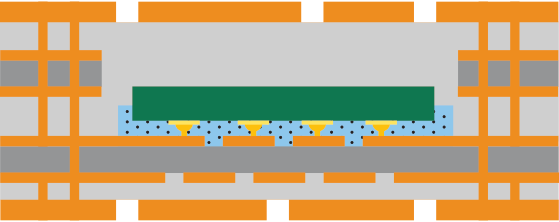

New techniques in Embedded components

• Bottom laser vias process

• Top laser vias process

• Flip-Chip process

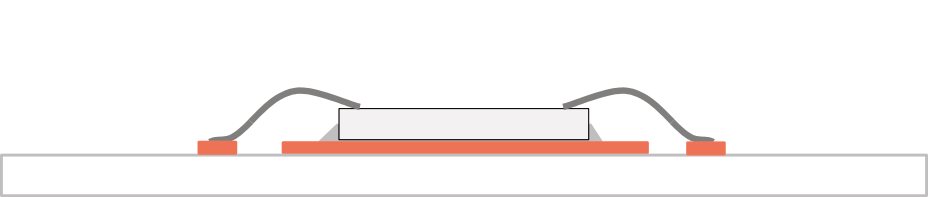

Wire Bonding

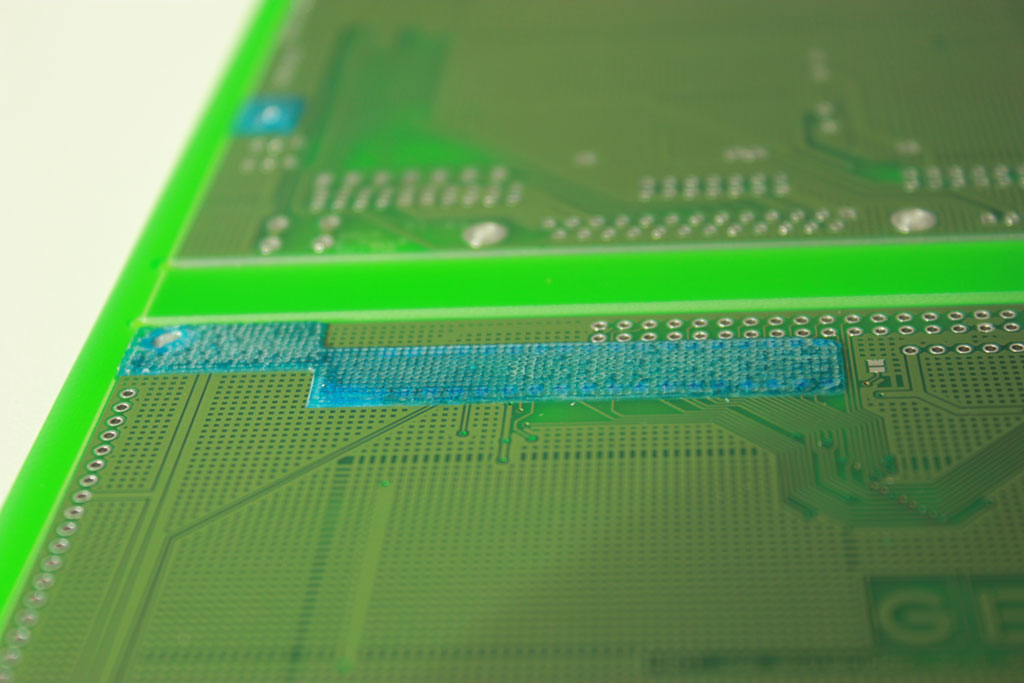

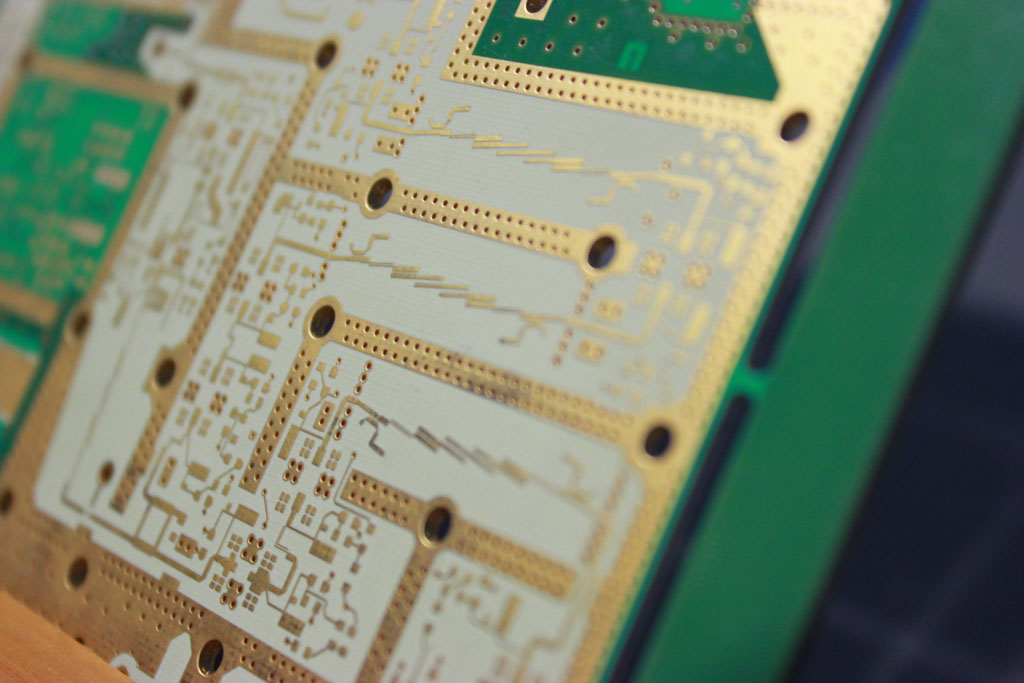

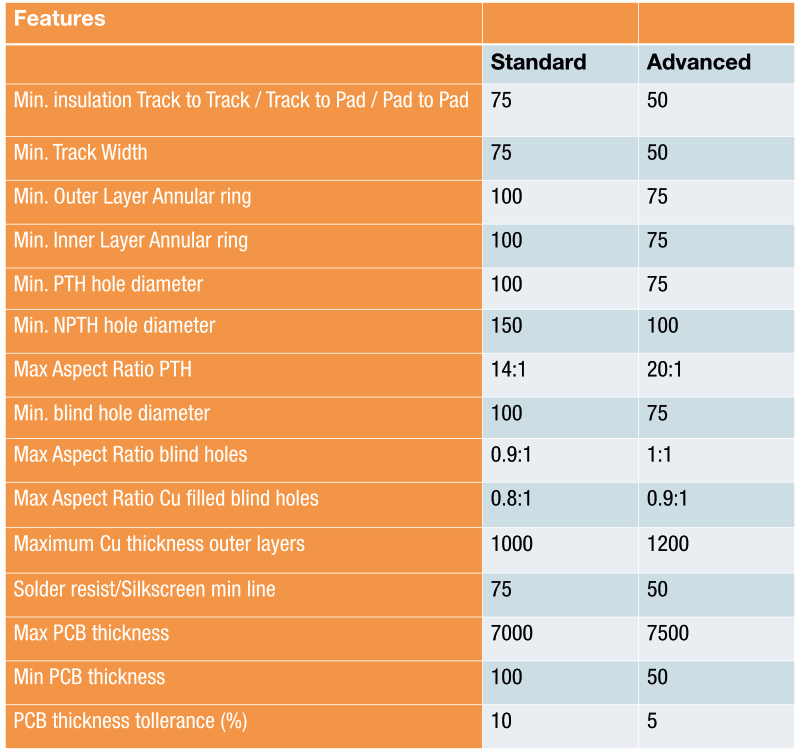

Capabilities on standard and special materials

Don’t you want METAL CLAD PCB’S?

We have the alternatives:

We are able to give better thermal performances without IMS and high electrical insulation without additional thermal interfaces with:

ELMANCBIS

Hybrid laminate for lighting and power applications

Benefits:

Increased component efficiency

Increased component life time

Reduction of device failures

Reduction in the size of the heatsinks

Reduction of the system size

Reduction of TIP costs

Integration of control circuitry with the power led board

TECHNOLOGY

Laminate production:

Excellent lamination of layers

Customization of the stackup to the product design specification (materials thickness and type)

Process and product optimization:

Centering techniques with X-ray

Mechanical works with custom tools

Peel Strenght Test and Support Adesion Test

Thermal Sink Test

Continuous improvement in R&D and in Quality Management System

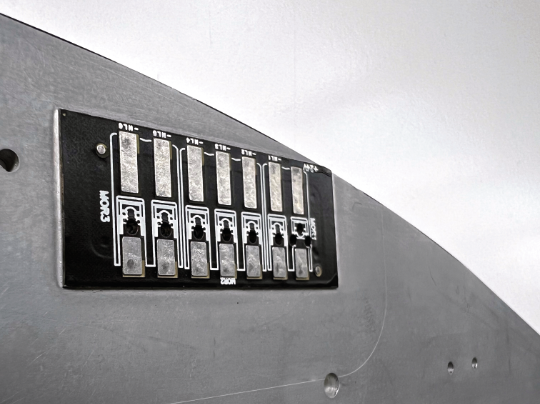

Non-standard techniques and configurations:

Direct Dissipation Techniques

Electrically isolated mounting, wired or connector holes through metal cladded materials

- Connections to power and ground from the bottom of the heat sink

- Isolated component through MC material

Possibility of soldering components or connectors from both sides - Aesthetic benefits: absence of insulated wires visible on the top

- Size reduction

- Simplified geometry of the boards

Bonding Techniques with Pressure Sensitive Adesives

Why choose Elman for your MCpcb’s?

Because Elman can improve your business thanks to:

Capability to supply pcb’s on its own production materials with better thermal and electrical proprierties and low costs

Optimization of the dimensions of the base material panels according to the size of the pcbs

Technology and flexibility

Research and continuous development

Excellent partnerships with the the world's leading IMS suppliers (Bergquist, Ventec, Rogers,...)

Contact

Phone: +39.0861.80671

Fax: +39.0861.806728

Via I Maggio, 23, 64015 – Nereto (TE) – ITALY

Sales & Marketing Manager

Monica D’Annuntiis

Phone: +39.0861.806731

E-mail: dannuntiism@pcbelman.it

Technical Manager

Flavia Natali

Phone: +39.0861.806744

E-mail: natalif@pcbelman.it

Purchasing Manager

Francesco Re

Phone: +39.0861.806739

E-mail: ref@pcbelman.it